|

|

#181

|

|||

|

|||

|

Thanks Ross.

I'll have a look. |

|

#182

|

|||

|

|||

|

Darren,

Congrats on your build! Because of the size of your MM did you feel it necessary to 'beef up' your frame or do you feel one can do with less beef. I just ordered steel for my frame (same size as yours) and I'm starting to think I didn't plan well enough. Tom |

|

#183

|

|||

|

|||

|

I will say I suffer from "overkill-itis", so bear that in mind.

I wanted room to store sheet goods under the table, so I couldn't triangulate as well as some have done. When the machine is doing some rapid moves, it is surprising how much even a heavy table moves. I'm talking reversing directions of the gantry at 150" per minute. If I had it to do over, I wouldn't make it any lighter. |

|

#184

|

|||

|

|||

|

Gonna use this image to make an 30" pub table top using 1/2" Corian and red epoxy.

Still deciding on a base.  |

|

#185

|

|||

|

|||

|

Darren,

At what speeds/# of passes are you cutting the corian and are you finding the dust an issue? Tom |

|

#186

|

|||

|

|||

|

Hi Tom, I use an end mill cutting .125" deep in one pass at 150" per minute. I have a homemade dust foot similar to many you see documented here, and dust has only been an issue when I forget to turn the collector on.

|

|

#187

|

|||

|

|||

|

less than 7 minutes later, the laces are cut.

Tom, you can see what dust is left in the pockets, pretty big chips really.  |

|

#188

|

|||

|

|||

|

Nice !

What end mill are you using for this? |

|

#189

|

|||

|

|||

|

1/4" upcut spiral.

|

|

#190

|

|||

|

|||

|

Couldn't get a plug for the MM forum, but a pretty good read nonetheless......

http://daily5remodel.com/index.php?a...cle&rowid=1799 |

|

#191

|

|||

|

|||

|

Nice article, nice business plug

! !Wishes it bring you more business. Good luck  |

|

#192

|

|||

|

|||

|

I'm hoping it brings more people here, through me, as well.

Much greatness can be achieved through many minds. |

|

#193

|

|||

|

|||

|

Nice Darren, well done.

|

|

#194

|

|||

|

|||

|

Darren,

I play around with corian/solid surface too. MM definitely speeds up the process. Do you have any experience with laser scanning equipment/systems for scanning templates? or does anyone for that matter. Just wondered if it would be a wise option. |

|

#195

|

|||

|

|||

|

Great write up on your work Darren.

An inspiration to the other Mechmate builders. Regards Ross |

|

#196

|

|||

|

|||

|

Whipped a few name plaques up for some great niece and nephews I haven't met til this weekend.....

|

|

#197

|

|||

|

|||

|

That's one way to remember the names

Ross |

|

#198

|

|||

|

|||

|

I think they have a new favorite Uncle.

|

|

#199

|

|||

|

|||

|

If still not, this would seal the deal

Great work, an inspiration for all of us still building one   |

|

#200

|

|||

|

|||

|

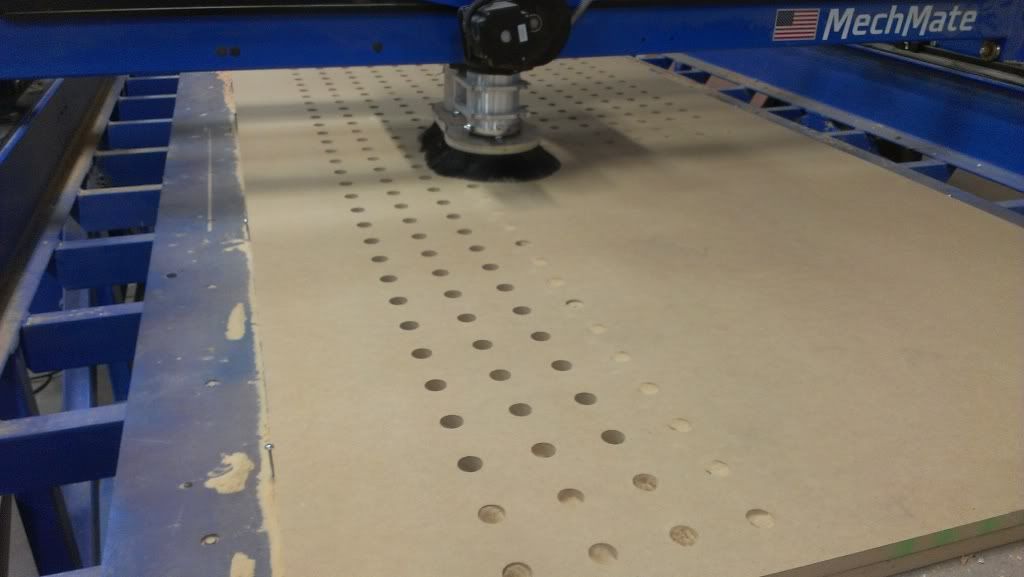

Figured I'd start making my own pegboard....lol

Actually its the top for a downdraft sanding station.  |

|

#201

|

|||

|

|||

|

Well, I know it works. you may want more holes closer spaced.

|

|

#202

|

|||

|

|||

|

Darren that is going to be a huge down draft table. Cant imagine the size of the blower you going to need.

|

|

#203

|

|||

|

|||

|

I'm going to use 2 HF dust collector fans mounted inside.

A buddy has a similar setup and it works pretty well. Should be (If you trust HF specs) roughly 3000 CFM. I'll still have the RO sander hooked to a shop vac too. We'll see. |

|

#204

|

|||

|

|||

|

Sure make life a lot easier with MM boring out hundreds of holes while you watch

|

|

#205

|

|||

|

|||

|

416 holes to be exact.

I'm going to make some 2" square blocks with 1" dowels, to insert in a hole to hold work for beltsanding. Beauty of a MM? If I need to make a top with a greater number of smaller holes, I'm only out the cost of 1 sheet of MDF. |

|

#206

|

|||

|

|||

|

Or just offset the pattern to put a hole in the middle of four adjacent holes. I think I'm explaining that right.. Kinda like looking down at a crap ton of dice sitting on 5.

|

|

#207

|

|||

|

|||

|

Almost everyone with a CNC at some point carves The Last Supper. I'm not overly religious, but thought I'd give it a go.

When my parents moved to Kentucky a few years before my dad passed, I was given the top to our dining room table, which he had made when I was a year old. His words were "cut it up and make something if you want, if not burn it." It was a pair of 6/4 15" wide sugar pine boards with a simple breadboard end, and had seen better days, being 40 years old at the time. Everyday lately, when I'd walk past it leaned up against the wall, it would whisper " are you ever gonna build anything with me?" Finally, I decided to cut it into four blanks, and machine a Last Supper carving on each blank. 1 for me and each of my three siblings. I picked a quiet day in the shop, and agonized over cutting up something my Dad had made while I was in diapers, but I felt pretty close to him after I got started, and figured it was a pretty fitting tribute to the Old Man who gave me my love for woodworking. WE fought like cats and dogs while he was alive, and I miss him a lot.  |

|

#208

|

|||

|

|||

|

Darren, I'm sure you'll cherish it always. Very nice.

|

|

#209

|

|||

|

|||

|

thanks for sharing a private situation as such.

Compelling !! .....and nice work  |

|

#210

|

|||

|

|||

|

Very nice Daren.

Lost my dad in Nov. 05, I still think of him everyday. He was a woodworker as well (and self proclaimed tinkerer). It is where I got my start and some of my best memories are of holding the end of a long board for him when I was 5 or 6 years old. Thanks for sharing! Mark |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| University Of Missouri Saint Louis Theater | ganderson | Introduce yourself and start planning | 8 | Fri 31 October 2014 17:53 |

| Starting my MM Build - St Louis MO USA | inventek2000 | Construction started, but not cutting yet | 38 | Sun 25 September 2011 17:51 |

| my machine cnc | marcoscnc29 | Archives | 1 | Sat 24 April 2010 17:58 |