|

|

#1

|

|||

|

|||

|

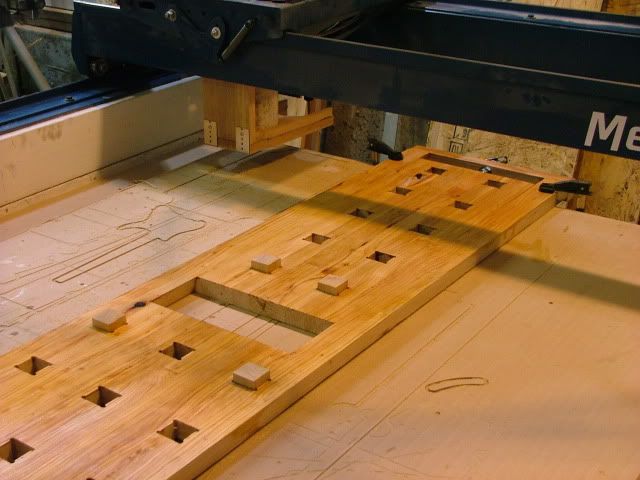

Another workholding setup

We're all influenced by our backgrounds. Here's the kind of workholding clamp a lumberjack might devise.

Top view, a sign blank is clamped in place.  Another top view with sign blank clamped in place.  Top view, nothing clamped. Note the dogs placed in the holes.  Underside view, showing the all-thread slot. I'll come up with a better handle knob eventually. I laminated a bunch of hemlock boards into one 102" x 16" x 1.25" plank. I then set my tablesaw at 15° and ripped the plank into three pieces by taking 2 1/2" off each long side. The center piece was then shortened 6 1/2". The remaining 95.5" long chunk was cut 30" from one end. The two edges and the longest center piece were then reassembled and glued. The plank now has a dovetail section in which the 30" long piece can freely slide. Now surface the whole thing on your MechMate, both sides, cut an array of 1 1/2" square holes, 6" on center in both the plank and the dovetailed sliding piece. Rout a groove and some crosswise notches in the underside of the sliding piece to accept a chunk of all-thread (I used 1/2") and nuts. Drill a matching hole through your end-piece and attach a handle to the all-thread. Cut at least four blocks, 1 3/4" x 1 7/16" x 1 7/16". Finish the assembly if desired. I used linseed oil. In use, it's necessary to clamp the assembly to the tabletop. Last edited by lumberjack_jeff; Tue 22 December 2009 at 17:27.. |

|

#2

|

|||

|

|||

|

Nice going Jeff…. I was just considering using a wood tall vise approach too !

It must be a woodworker thing  Thanks for sharing ! BTW, how are you enjoying your wood table set up ? Is it to YOUR satisfaction & tolerance ( finished work by the router that is !)? Amicalement, Robert  |

|

#3

|

|||

|

|||

|

Thanks Robert,

The table has been great, it is really quite stable and solid. Once you surface the spoilboard, everything is flat to the cutting tool. There are lots of challenges to work through, but the table really isn't one of them. |

|

#4

|

|||

|

|||

|

|

|

#5

|

|||

|

|||

|

Aaah a 5 horsepower forklift

|

|

#6

|

|||

|

|||

|

My favourite forklift pics:

|

|

#7

|

|||

|

|||

|

I like the last pic.

|

|

#8

|

|||

|

|||

|

There is an explanation... I don't see the "handle with care" sign on the bomb

|

|

#9

|

|||

|

|||

|

Lol!!!

|

|

#10

|

|||

|

|||

|

I love the upper photo, I respect "git 'r done" guys.

But I'm unsure what the guy standing on forklift "A" holding on to forklift "B" thinks he's doing. (I'm sure the operator in the bomb photo is absent because he's in the locker room changing pants) Last edited by lumberjack_jeff; Thu 28 January 2010 at 21:33.. |

|

#11

|

|||

|

|||

|

The guy on forklift A is the "active counter weight system" When the load on forklift B is removed he is supposed to jump off

The Driver of the second forklift is not in the locker room.. He was last seen jumping over the far fence, in a single bound and has not been seen since  |

|

#12

|

|||

|

|||

|

Claus, look how you have messed up Jeff's thread!

|

|

#13

|

|||

|

|||

|

I am sure Jeff doesn't mind. ... He is just thankful not to be in one of Gerald's forklift pictures!

|

|

#14

|

|||

|

|||

|

Cameras are banned from any of Jeff's Git-R-Done adventures.

|

|

#15

|

|||

|

|||

|

Table Hold-Down

Jeff:

Thanks for the hold down concept and photos. I am starting to build one for myself. Great idea and execution. Joe |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| mach 3 setup help | paul60 | 70. Control Systems | 7 | Tue 03 August 2010 11:02 |

| Setup document "Mach3 CNC Controller - Software Installation & Configuration" | Gerald D | CNC motion control software | 4 | Fri 08 January 2010 10:34 |

| Table Design for twin spindle setup | Travish | General - MM Build | 7 | Fri 09 October 2009 19:08 |

| Looking For help to setup my CNC Router - to visit in Northern California | Mcyoda | Construction started, but not cutting yet | 0 | Sun 27 July 2008 18:45 |

| Cannot get motor to turn - Mach Ports & Pins setup | kalimero | Troubleshooting | 18 | Tue 06 May 2008 09:50 |