|

|

#1

|

|||

|

|||

|

Now VFD Chillin !! #125 - Mt Clemens, MI

Parts are arriving!

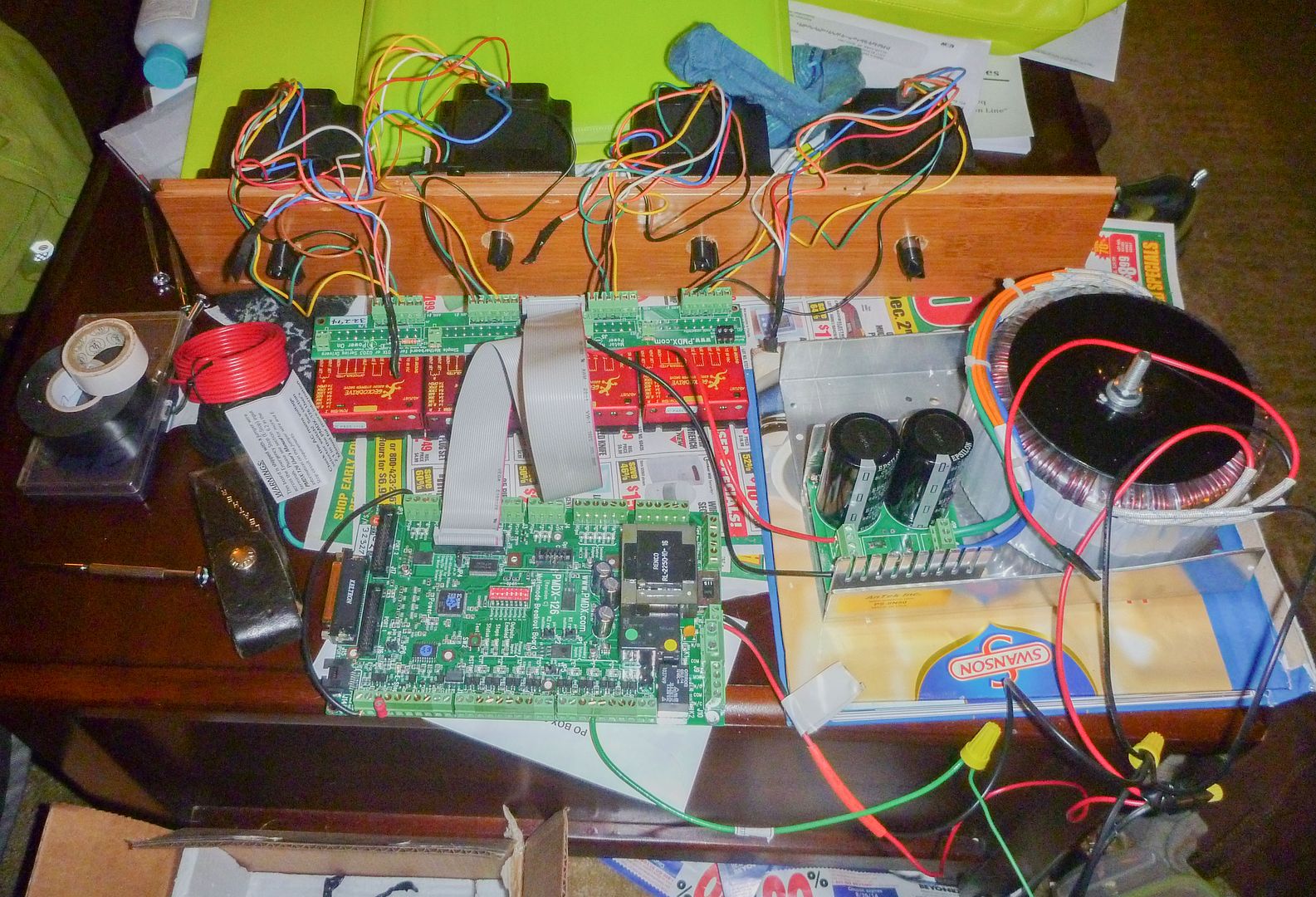

Once I had what seemed like a critical mass of pcs in my shop-  Antec 50v 1000w (Too big- I got a deal on it. For now, I'm just using one primary. Output measures 48.7v) (4) KL34H280-45-8A steppers, wired half coil PMDX 126 & 134 (4) Gecko 203 It seemed like time to graduate to the kitchen table. It seems like the shop table might work better, but hey- the kitchen table comes highly recommended.    I didn't have much time before I had to take my girlfriend to the airport, so I graduated to her coffee table. (There is MUCH CHAOS here, this is the best workspace I could get while she packed).  Once I figured out the settings of the DIP switches to select which drive I was testing, everything was a breeze and made all the proper whirring sounds at the right times. The motors all moved as hoped and all the magic smoke stayed inside. Of course, I didn't have resistors even close to what I needed for limiting the current of the Geckos, so I got to give RadioShack a few dollars. It's amazing that I can have so many parts and still not have the RIGHT little bit when I need it. The wire nuts are just for this test, and only on the AC side. All the unused wire ends are taped to avoid surprises. I'll order some pin terminals for the low voltage stuff before it's time to build the control box. My control box kit is ordered from Mike. Once that appears, I'll do a full kitchen table project with the contactor, switches, and other goodies. I'll start on my table (maybe tomorrow), and I'll order the laser parts kit once I can get to the bank to replenish my available funding. |

|

#2

|

|||

|

|||

|

Great progress!! Your Control Box will be on its way shortly.

|

|

#3

|

|||

|

|||

|

Thanks! (Actually, no real hurry on the control box. I have PLENTY to keep me busy.)

|

|

#4

|

|||

|

|||

|

Progress update-

2 GIANT boxes of goodies arrived from MetalHead- the control box & innards and the laser kit & belt drive plates. Surprisingly, wiring up most of the control box was pretty straight forward. 2 hours of wiring and about 20 minutes of troubleshooting and all the lights, switches, and the contactor were working properly. I connected my drives and everything seems to work in test mode. I still need to wire in the Estop circuit and router control, but I understand how it should all work. I think. It's not pretty, but it works. About half the wires are labelled- I seem to have a short attention span while running a label maker. More boxes have been coming in from McMaster and others, and an ESS is on the way. Many people at TechShop have been offering help, including some builders and designers of various CNC machines. I'm trying to soak up all I can. There are also a fair number of people asking what speakers I'm going to be running with the amp I'm building  It turns out the steel I bought for the main beams is far too light, so I'll use it for some other project. It was cheap. Next week I'll make the rounds of the local salvage yards and hopefully find something suitable and within budget. Next up- label the remaining control box wires and transfer the control box parts into the actual control box, which means I need to think about the actual positions of the switches and indicator lights. Hmmmm. It's also time to start welding the Y-car, and start building the Z slide. |

|

#5

|

|||

|

|||

|

Fun Times!!

|

|

#6

|

|||

|

|||

|

Update-

Still pressing on, it's just been hard to find time around the holidays, especially with phone calls like "Merry Christmas Mr Landlord, your roof is leaking." Fun stuff! It took me a bit to find a config file for Mach3. I used the one from CNCRouterParts, here: http://www.cncrouterparts.com/mach-3...les-p-161.html Everything seems to be working fine. I still have to set the steps/inch & lots of other parameters, but so far all the magic smoke is still inside. I also cut my Z slide today, assembled the skate (I still need the eccentric bearings- lots more $$ to spend) |

|

#7

|

|||

|

|||

|

Another update-

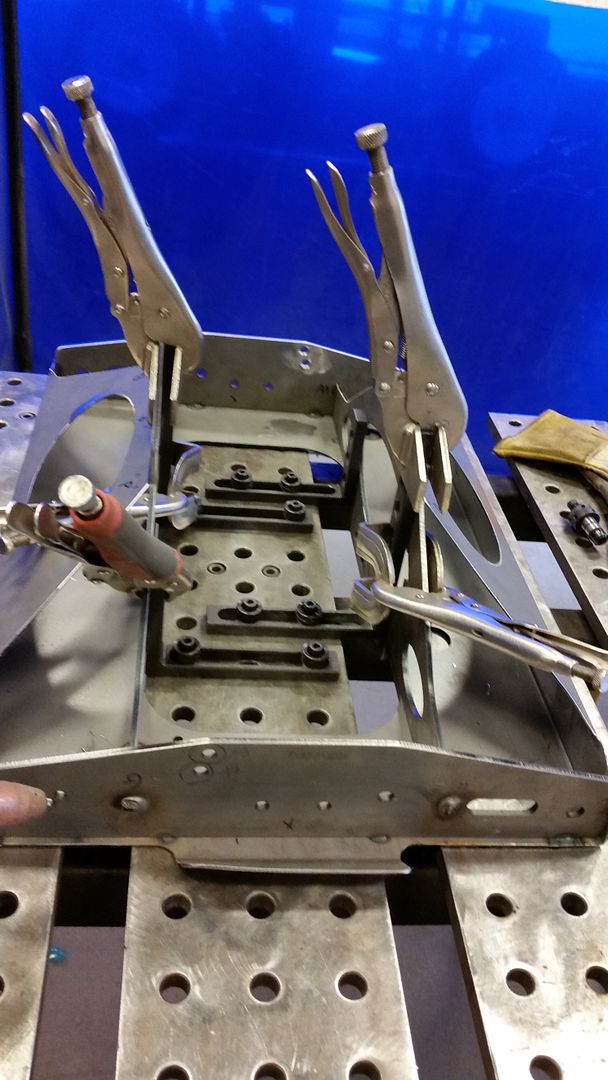

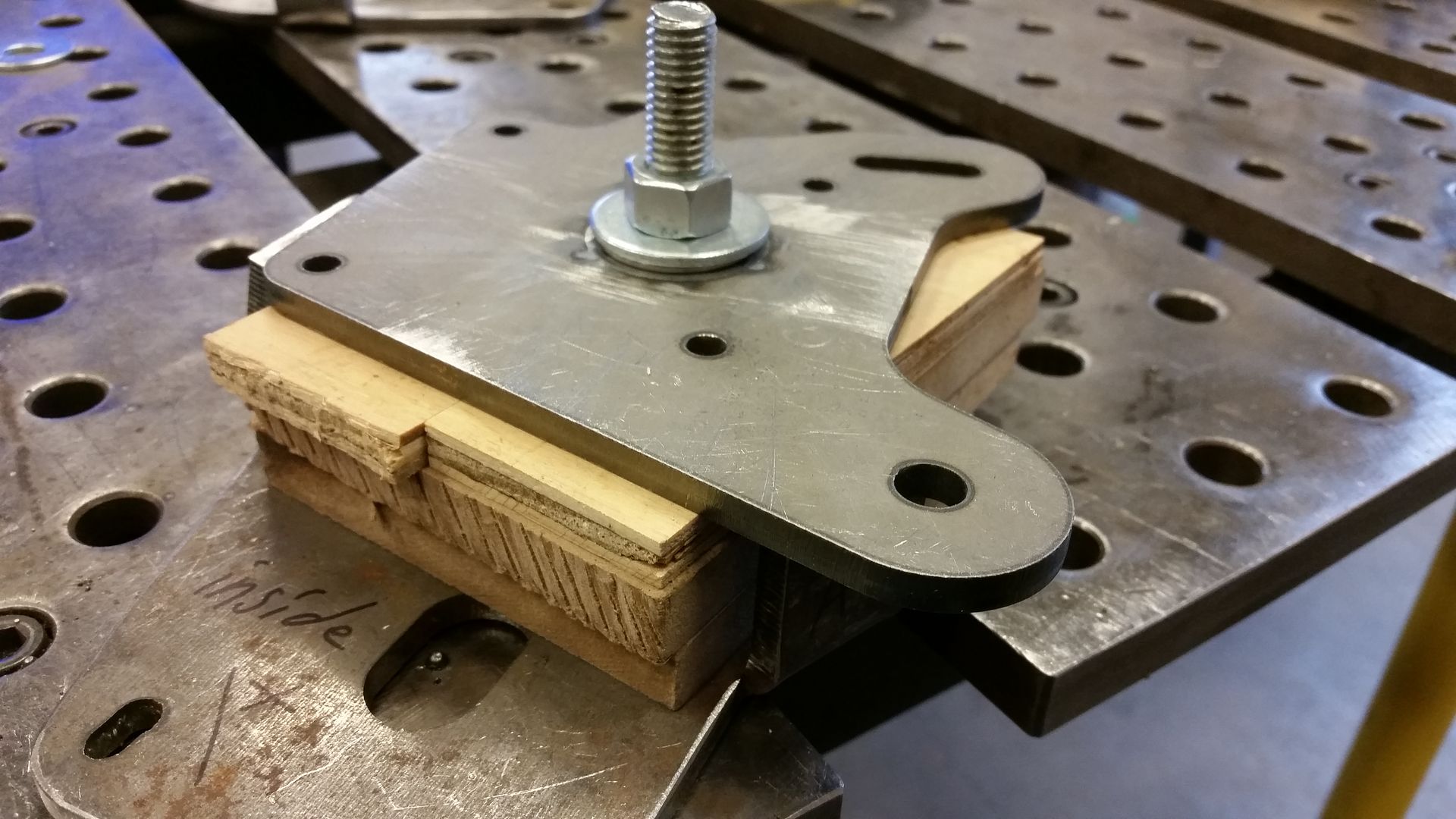

I'm making progress. My Y car and gantry are welded & painted, Z-slid is done, my belt drive parts are here & the belt drive plates are welded up. Of course, I forgot to allow for the flange on the small drive belt pulley, so I ordered belts a wee bit too short. Thankfully, it's one (well, 4) of the cheapest parts so far. I'm running out of small pieces & assemblies to make. I think my next projects are to put my kitchen table project into the control box and paint/assemble my belt drives. Then it's onto grinding rails & building the table. And making a place to put the MM... I'll worry about that later.... I'm really impressed with the plans and the level of detail in the forum here. So far, I've found answers to most all my questions relatively easily. That said- Question- I'm planning to power my router through an SSR in my control box. Is it better for me to wire the router direct to the SSR, or to wire the SSR to a 110v panel receptacle in the side of my control box? Something like this:  I've been negligent taking pictures of my build. Here's a few I've taken with my phone. Getting ready to weld the Y car:  Paint!  Welding the belt drive plates:  Hey- everything fits!  |

|

#8

|

|||

|

|||

|

Lookin good!

|

|

#9

|

|||

|

|||

|

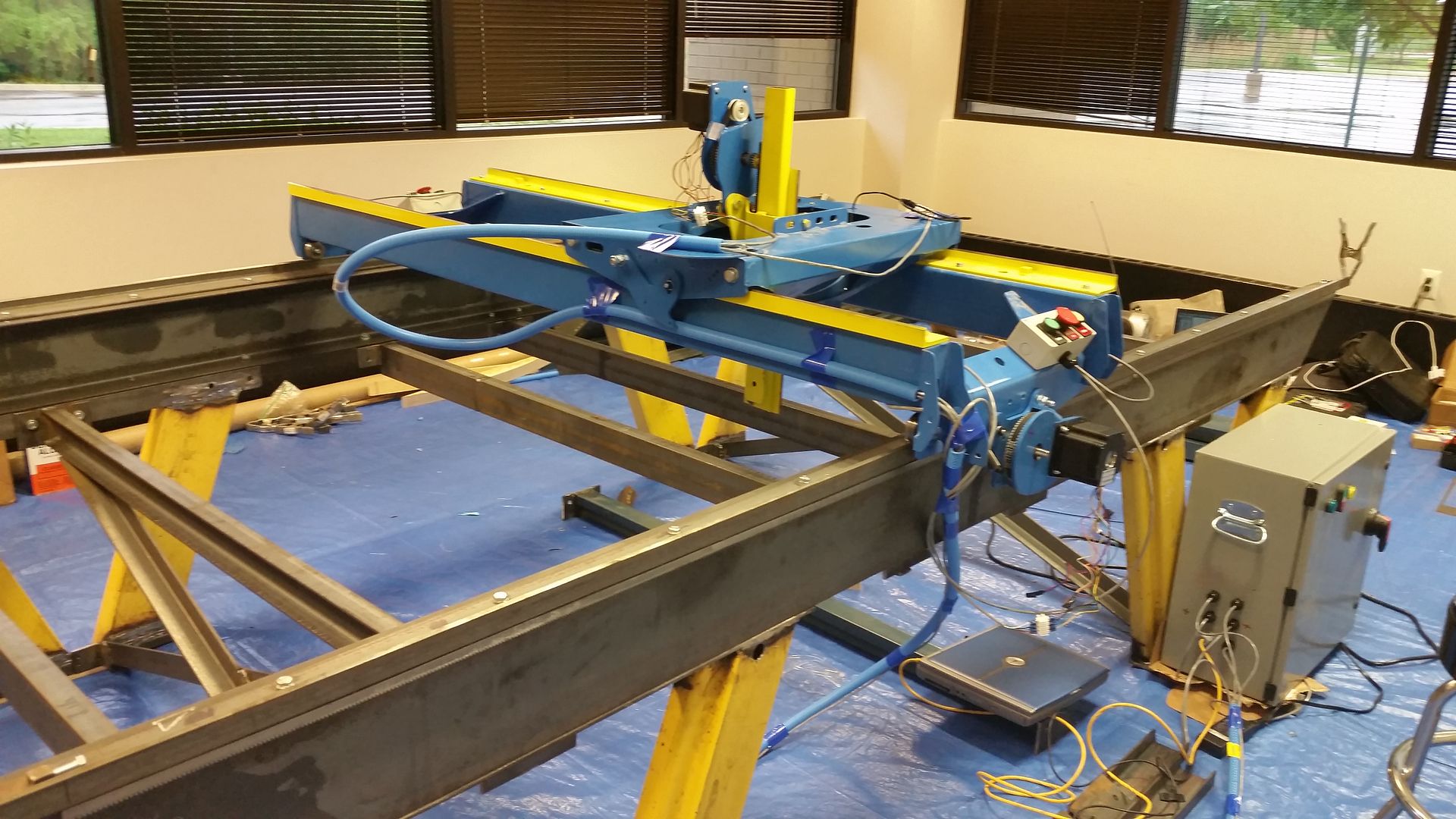

It's ALIVE!

Bwah ha hah!! I've been feverishly working both my real job & building this beast of a machine. So far, I've not run into any real problems. I welded some belt drive plates wrong, got my X rail stops in the wrong place, and a few other mistakes, but nothing too drastic or upsetting. Yesterday I wired all the motors. Today, I connected the brains, and everything seems to work & move as expected. The wiring, flex conduit, and general chaos are all temporary & will be replaced. In 14 days I need to move the machine, and hopefully have it running for a CNC workshop. It looks like one of my X-beams has a pronounced bump of maybe 2mm, right about in the middle. I'm hoping I can get it to the mill & face it. Otherwise, I guess I'll be using the angle grinder. Other ideas? Overall, so far, so good!  |

|

#10

|

|||

|

|||

|

Looks and sound familiar... Good luck! Handheld beltsander will also do the trick, and is easier to flatten a bump to a relative straight then the angle grinder, where you can quickly create a wavy surface. Milling is even better but seems overkill to me as you will have trouble mounting it and need to shim anyway.

Btw if you use the sanding disk on the cutting disk method (used for angle on rail) it might also be a nice idea, to be able to flatten the high part to the rest of the beam. All this assuming you have a larger surface that is bumped 2mm higher. Last edited by Fox; Sun 31 May 2015 at 07:49.. |

|

#11

|

|||

|

|||

|

I haven't done more than eyeball it, it looks likes I have maybe 8 or 10 inches of beam that will need to be surfaced.

I like the belt sander idea. Much more control than an angle grinder, and I don't have to get the beam mounted in the mill. I got the soft limits working today. Not having a " - " sign in front of the numbers in the Z axis was making it angry. |

|

#12

|

|||

|

|||

|

The belt sander worked very well for me on a number of other occasions working with some steel, although it's intended for wood originally, but quite powerful, and on the mm I used it to remove the scaling form the steel cause it won't dig easily, and has a flat metal plate on the back to support the belt.

Mine was big enough to cover the entire I-beam width, so I worked it a bit diagonally along the surface. It won't remove a crazy amount lot of material at once, so it's easy to control it to the sweet spot. I worked it with high pressure ( almost stalling ) to remove a lot of material, and when almost there just almost let it ride on it's own. You could even keep an old spray can handy, when you spray the surface in between your sanding you can easily see the high and low spots on your surface. Don't try to to make it perfectly flat though, you just need to take away the bumps and the scaling a bit, the rest will shim away. I think I spend and hour on my two 3 meter beams all together. Dust warning though ( everything becomes very black from the metal dust ;-) ) Last edited by Fox; Mon 01 June 2015 at 02:57.. |

|

#13

|

|||

|

|||

|

Hi ChuckS! Great machine!

What reduction are you using on stepper motores? BR, Cristiano |

|

#14

|

|||

|

|||

|

1:3.6 belt reduction

20 tooth & 72 tooth pulleys |

|

#15

|

|||

|

|||

|

Thanks! Where you bought those reduction?

|

|

#16

|

|||

|

|||

|

They came from http://www.bbman.com/

Here's what I ordered. !! I ORDERED THE BELT 2 TEETH(?) TOO SHORT !! Product Information Product Name Part No. Quantity Item Price Total Price 162XL037G 162XL037G 4 $6.43 $25.72 20XL037-6FA6 TOO SHORT! 20XL037-6FA6 4 $11.77 $47.08 72XL037-6WA6 72XL037-6WA6 4 $32.03 $128.12 Subtotal: $200.92 Shipping & Handling: $10.82 Tax: $0.00 Order Total: $211.74 |

|

#17

|

|||

|

|||

|

It's alive!

Here's it's first autonomous test run. It's set up in a nice, pretty room for the CNC workshop at TechShop Detroit. https://www.youtube.com/watch?v=IIbE...ature=youtu.be I still need to flatten the X-beams and paint most of the table steel, build the actual table surface, replace my wiring with something more permanent- still lots of fun to have. |

|

#18

|

|||

|

|||

|

Looks like your video is set to private. Looking forward to seeing it move.

|

|

#19

|

|||

|

|||

|

#20

|

|||

|

|||

|

The link in the #17 post works. Looking great. Nice to see it come to life!

|

|

#21

|

|||

|

|||

|

My MM is assembled & mostly adjusted. Yay! Pics to follow sometime...

I'm losing my current shop, so I no more nice electric service, heat, AC, or space.  The MM is now in my garage. I can work around the power & general lack of space, but- This is an un insulated, unheated garage in Michigan. Winter temperatures here are typically below freezing for a few months, and occasionally might hit -15F (-25C) for a few days. I'll be insulating the garage before winter, mostly for noise reduction to keep the neighbors happy. Should I also be looking for some kind of heat to keep the MM happy? (I'm used to working outside & teach winter camping. I'm OK in the cold.) |

|

#22

|

|||

|

|||

|

I think your MM will be fine and will actually emit some heat into the shop. Good luck in that state up north : )

Mark |

|

#23

|

|||

|

|||

|

I would not let the control box freeze up. Electronics don't like temperature shocks like that, and condensation might become an issue, when you start it up and things become warm, like heats inks and such. Your pile of steel does not care of its cold or hot. It shrinks and expands a little, that's all.

|

|

#24

|

|||

|

|||

|

Thanks!

Re condensation- it would be pretty easy fill the few holes in the control box and to occasionally purge the air with DRY air from a SCUBA tank or other source. I'd never get the box "air tight", but maybe purging it before use would cut down on any condensation. It would also be easy to rig up some kind of heater to pre-heat the brains before use. I'll have to put my thinking cap on, once I find it. |

|

#25

|

|||

|

|||

|

Don't forget yourself. You will have to be close to the machine often, so you share the climate. Insulating the shop will increaese production and joy tremendous.

|

|

#26

|

|||

|

|||

|

The local big box store has insulation on sale, so I'll be buying a bunch. Yuck. But, I only have to do it once, and I'll be happier all winter.

I just wish I was not planning on selling the place in a year. The next place will have a proper shop, or at least enough room so I can build one. |

|

#27

|

|||

|

|||

|

Lots of small MM projects done. Dust collection stuff is on the way, new shop lights are in, the spoil board is ready for surfacing, the control box has been rewired a bit to use 110v instead of the planned 220, and people are lining up to hand me money

A friend is loaning me a fancy laser device made for leveling & truing CNC machines. I've got it as close as I can get it with tools I own- it will be interesting to see how I did when compared with high end tools. Here's a video of my MM counterboring the holes for the elevator bolts that hold the table top to the Y beams. Exciting stuff! It's a steep learning curve making friends with Mach3 & the tool pathing programs. So far, I've not broken anything, just some extra gouges in the bottom of the spoil board. https://www.youtube.com/watch?v=OiRcjYsbvYE |

|

#28

|

|||

|

|||

|

Guess we need to get you a number!!!!

|

|

#29

|

|||

|

|||

|

And in a cruel twist of fate, the phone for my current biz has been ringing off the hook. Making money is going to interfere with finishing my MM, which hopefully will make me more money....Hmmmmm. I won't complain.

My girlfriend's BIG BOSS gave her a pair of tickets for the University of Michigan football game on Saturday, so there goes another chunk of time. Football is not my thing, but a few hours away from work sounds pretty good. Full speed ahead! |

|

#30

|

|||

|

|||

|

Enjoy that 12" of bench they give you in the Big House. I've been there once, and it's something to experience.

Btw, enjoy the screenset. Thanks.  |

|

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| Newb in Mt Clemens, MI, USA | ChuckS | Introduce yourself and start planning | 21 | Wed 18 January 2017 20:42 |