|

|

#541

|

|||

|

|||

|

I have to agree, I like Darren's old thread title better. The new one makes it seem like something is wrong with Aspire.

|

|

#542

|

|||

|

|||

|

That is nice to hear that they can respect the MM. Especially considering that we don't have our machines because of a stroke of the pen on a checkbook!

I was not familiar with the Camaster, so naturally went to the website. Nice looking machine, and some good stuff in the applications section. Gave me more ideas of what to make....so little time  Mark |

|

#543

|

|||

|

|||

|

I like your new title. It is an accurate representation of where you are at this moment. Nice you got some a recognition at the event.

|

|

#544

|

|||

|

|||

|

This was a nice perk, along with a T-shirt.

|

|

#545

|

|||

|

|||

|

Super sweet if you're a hat guy.

|

|

#546

|

|||

|

|||

|

Wow!.

Did you carve that hat on your machine ? Can you do T shirts to match.  |

|

#547

|

|||

|

|||

|

You know he can do just about anything including t-shirts

|

|

#548

|

|||

|

|||

|

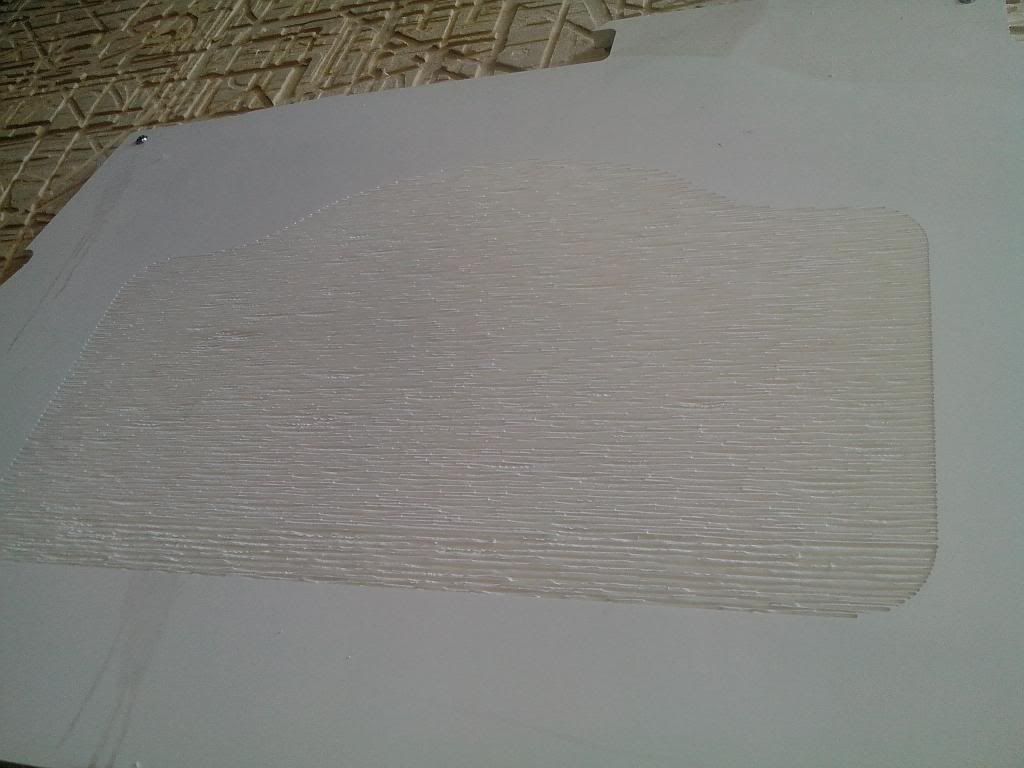

Finally got it primed and the white paint done...

|

|

#549

|

|||

|

|||

|

Looks Nice Darren!

What is the material...I saw the earlier picture...is that MDF? Hope you have been feeling well too. Mark |

|

#550

|

|||

|

|||

|

Thanks, Mark.

It is 1/2" MDF. |

|

#551

|

|||

|

|||

|

Awesome...thanks! I have never done much with MDF, but the end results sure look good.

It is on my to-do list. I sure hope I live to 105 so I can get through the first half of my list  Mark |

|

#552

|

|||

|

|||

|

I use it for stuff to hang on the shop walls, usually its scrap left from radius template work I do for a millwork shop.

No such thing as scrap anymore.  |

|

#553

|

|||

|

|||

|

Mark, painting the edges with 1/2 water 1/2 wood glue with a light sand will give a even coating of paint all around since MDF is like a sponge. The end result will look like formed plastic with the right paint.

|

|

#554

|

|||

|

|||

|

Thanks Pete. Another good tip...I appreciate you sharing your experience!

And Darren, no truer words....now when I see a tiny little scrap...I am like "that could make a keyring"  Mark |

|

#555

|

|||

|

|||

|

I have had real good luck using an alkyd primer instead of the glue/water mix. It seems to not raise the ends as much. The stuff I used also sands really well.

|

|

#556

|

|||

|

|||

|

Thanks Heath...I've got some of that on the shelf, I will give it a try!

Mark |

|

#557

|

|||

|

|||

|

I used some rattle can automotive sandable primer and white spray paint I had laying around.

A detailed design limits the sanding time I'll devote, but this was relatively simple, and my main objective on these types of things is zero out of pocket, using whats on the shelf, that might otherwise go to waste. |

|

#558

|

|||

|

|||

|

House Numbers

Had some scrap 1/2" PVC laying around so I drew up a quick plaque for some house numbers.

The border and numbers will be male inserts using the Aspire inlay function and the background was made using the built in texturing tool. By pocketing the numbers and border, the texture can run right through the numbers with a crisp edge showing no tooling marks. It also will be easier to paint everything apart since I want the border and numbers to be a different color than the background. I'll try and cut it out tomorrow.  |

|

#559

|

|||

|

|||

|

where do you but 1/2 PVC?

|

|

#560

|

|||

|

|||

|

The local Home Depot stocks it in 4x8x1/2" sheets for a hundred bucks a sheet.

The brand name is AZEK. It is available up to 1" thick, I believe. This will be leftover from a sign I built for a restaurant that took 7 sheets, even with creative nesting. |

|

#561

|

|||

|

|||

|

It is not available at every Home Depot unfortunately.

|

|

#562

|

|||

|

|||

|

I remember seeing a video on that on one of the Vectric discs. I have never run a texturing project so I am eager to see your result.

|

|

#563

|

|||

|

|||

|

Pete

It was not available at my Home Depot either, but had free shipping. And it was faster to have it shipped to my home rather than the Home Depot store. Mine has arrived, I opened it just to check it out. I like the look/feel of it, I would think it should machine nicely (but haven't got to use it yet)...but have my first sign job  Mark |

|

#564

|

|||

|

|||

|

Faster speeds/slower RPM than hardwood, else you'll melt the plastic back onto itself.

I run my router as slow as it'll go, prob. 11k RPM and 150ish IPM. |

|

#565

|

|||

|

|||

|

Texturing as we speak.....

I can already see that orienting the line of cut along the Y-Axis would be beneficial, there are a lot of starts and stops and the Y-car is lighter than the Gantry... This will be a test of how good my machine really is. |

|

#566

|

|||

|

|||

|

Thanks Darren....I hope to do a test cut soon...I will use your numbers.

Mark |

|

#567

|

|||

|

|||

|

Just a guideline, Mark....Your Mileage may Vary.

|

|

#568

|

|||

|

|||

|

Darren,

I cut acrylic and polycarbonate at 8000RPM at 100 ipm. HDPE will melt at this speed, I am thinking PVC is probably fairly close in terms of machining speeds and feeds. Your opinion; have you ever cut HDPE? |

|

#569

|

|||

|

|||

|

I have not cut HDPE. My router wont go below 11k, (Super PID is mounted but not hooked up yet..) I bumped the speeds to 150 IPM to increase the chipload.

|

|

#570

|

|||

|

|||

|

Texture cut first.

Then pockets  Finished up.  Another zero out of pocket practice piece I can use. |

|

| Register | Options | Profile | Last 1 | 3 | 7 Days | Search | Today's Posts | Mark Forums Read |

| Thread Tools | |

|

|

Similar Threads

Similar Threads

|

||||

| Thread | Thread Starter | Forum | Replies | Last Post |

| University Of Missouri Saint Louis Theater | ganderson | Introduce yourself and start planning | 8 | Fri 31 October 2014 17:53 |

| Starting my MM Build - St Louis MO USA | inventek2000 | Construction started, but not cutting yet | 38 | Sun 25 September 2011 17:51 |

| my machine cnc | marcoscnc29 | Archives | 1 | Sat 24 April 2010 17:58 |